:: Diary - November 2011 ::

:: Friday, November 4, 2011 ::

I've been a bit busy this week so I haven't been able to get on with the car.

I got a plastic brake fluid reservoir today, and I bought a new brake clevis pin during the week, so I've got all the bits I need to change the servo. I

was thinking last night though (this is never a good idea) that I'll have to bleed the whole brake system after I've changed the servo - now I know the

front calipers will be ok, I bled them recently, but the rear wheel cylinders are old, and haven't been bled for ages, so I doubt if the bleed nipples

will move. So my first task today is to see if they do!

Short answer is no, they don't. Despite a plentiful supply of penetrating spray, they are stuck fast. They are also rounded off, the rust is so bad. I can

get a mole grip on but they are angled slightly so I can't get a good turn without the risk of breaking them off. I'll need to take the wheel cylinders off

to get the nipples out - but if I'm going to take them off, I'll just change them, they are only a tenner.

I'm not starting that just now though - the garage is already littered with boxes of carpet, plus the seats and the rest of the interior. I need to get

some of it back together before I start pulling other bits apart.

So - back to the carpet (as the bishop said to the actress). I've already done one wheelarch, so let's start with the other one! Same procedure as before

- I stick the carpet on to the top seatbelt mount, then the wheelarch, then the vertical bulkhead behind the seats.

The next bit to go on is the inner sill, which is one piece with the outside of the footwell. I line it all up so that the bound rear edge is in the right

place, and notice that the front edge of the door opening is miles out. Then I realise that it's cut to fit an S1 / S2 - and mine has longer doors so I'll

need to trim them. I run a permanent marker around the edge of the door, on the rear of the carpet, and also mark where the heater hoses go through the

bulkhead, and then remove the carpet and trim it to shape. Another refit to check, and then remove, spray with adhesive, and refit. It's a bit of a faff

to pull the carpet forward past the pedals, but I eventually get it all nice and smooth, pushing it into the edges and the mouldings in the floor under

the seat. A final trim with a knife, and it looks good!

Then I stick down the vertical bit behind the door - it covers the edge of the wheelarch and also the big body mounting bolt. I only stick it down

temporarily - I'll need to lift it later to bolt the roof hinge back on.

:: Saturday, November 5, 2011 ::

I start by carpeting the other sill and the vertical bit, then it's time for the rear bulkhead. I position it and the stick it on from the bottom up, making

sure that the edging fits properly around the wheelarch. Then I trim the top edge back by about an inch and glue and tuck the edge under the trim that holds

the rear of the roof on. Then at each end I leave the carpet unstuck - the top of the rear door pillar is open, and I'll have to work out how the carpet fits

to cover that up. There is also a strip of velcro that fits on somehow to hold the edge of the roof down.

Then I cut through the carpet in line with the holes in the bulkhead, and then install the roof hinge bolts, tighten up the nuts inside the pillar, and then

restick the carpets down. Then I trim along the rear of the door gap, and then reinstall the door seals around the edges of the tub.

Then I cut through the carpet in line with the holes in the bulkhead, and then install the roof hinge bolts, tighten up the nuts inside the pillar, and then

restick the carpets down. Then I trim along the rear of the door gap, and then reinstall the door seals around the edges of the tub.

It looks good!.

It looks good!.

Then I mark through the holes for the roof struts, and drill through the carpet from the boot, then reinstall the struts. The door rubbers aren't finished

in this photo - I need to finish trimming the carpet around the tops of the door pillars first.

Then I mark through the holes for the roof struts, and drill through the carpet from the boot, then reinstall the struts. The door rubbers aren't finished

in this photo - I need to finish trimming the carpet around the tops of the door pillars first.

Then I carpet the drivers side of the transmission tunnel - again it's a single long piece, so it's awkward - but I get there! Then I fit the 3 carpets on

the floor - there's a bit at the back that's under the seat, a small bit at the front, that needs a hole cut for the steering column to go through, and then

a floormat between the seat and the pedals.

I've run out of adhesive, so that's me finished for today!

I also walk along to the farm and bring the Cerbera back to the house for the Car Club meeting tomorrow.

:: Sunday, November 6, 2011 ::

I intended to wash the Cerbera this morning before I set up, but it's really frosty so for all sorts of scientific reasons, I decide not

to risk it. Plus I can't be bothered.

Vastly depleted TVR meeting at Dave's house this month - Dave's is hibernating over the winter, while Jim's is awaiting exhaust and oil

filter surgery. Mike turns up eventually though, so we set off, with Mike gallantly acting as squadron commander, Dave's borrowed a Porsche,

and Jim comes with me in the Cerbera. With the heater on.

We arrive at the hotel in time for a nice lunch. Dave cheers me up by reporting that the right hand exhaust is chucking out loads of fuel

when I accelerate hard - maybe that explains why I left behind a peleton of 4 choking cyclists after I zoomed past them. Why do 4 cyclists

insist on riding 2 abreast on busy NSL roads? They had that kind of "militant tendency" look that some cyclists develop to intimidate old

ladies into letting them bumble along chatting, so I think it was deliberate. A dose of full throttle acceleration to get past, probably

didn't cheer them up. Anyway the main point is - I'll have to check the Cerb on a laptop just to make sure nothing's amiss.

I meant to have a look at how the carpet fits around Mike's hood hinges, but he pissed off home as soon as he'd hoovered up his lunch - he

had to refit the door to his house so that his wife could go out and leave him alone and know he was safe. Or something.

After much interesting chat, it's time to head for home. I was hoping to get back in time to get the Cerb along to the farm before dark

o'clock, (they don't answer the door in the dark) but by the time I drop Jim off, I'm a wee bit too late. It'll have to stay at the house

till at least Thursday then - I'm working all over the place this week (that bit's just for Adrian, in case he's thinking I've got an easy

life while he's busy lying beside the pool in Bali).

:: Sunday, November 13, 2011 ::

Apologies to amy visitors dropping in to find out what progress I've made over the past week. The answer is - none at all! I've had a really busy week at

work, plus a couple of other things to sort out, then on Friday four of us went down to Birmingham to the Classic Car Show. We left at 4am and got back at

1am on the same day (well, an hour into the next day I suppose) but it was just superb. We also visited the Top Gear Live event which was also really good.

I managed to pick up some new pop-studs for the handbrake gaiter (it was only held on by one) and some brochures for other bits of rubber trim, seals etc.

What I forgot to buy was carpet adhesive.

I do get out to the garage for a wee while today, mainly to tidy up some of the crap that's lying about.

I measure up the door seals, and find those in the catalogue I picked up at the show on Friday. I also measure up the seals on the roof panels - the ones

where the panels overlap are also easy enough, but the sections along the edges of the roof (the top of the side windows) are an odd profile and aren't

there. I want to make sure I have new seals before I try to remove the old ones to replace the roof lining, so I'll have to try to source those.

Then I return to freeing up the rear brake nipples, so that I can bleed them after I change the servo. They are now chewed to hell, and even mole

grips, don't. But I've remembered those Irwin bolt grips I bought when I did the exhaust manifolds, and once I've found the right size, and given them a

dose of freeze-and-release spray, the nipples come out no problem at all. I nip them back up again till I'm ready for bleeding - I'll put new nipples in

at that time.

Then I remove my new secondhand brake reservoir from the old master cylinder I bought, and clean it up ready for fitting. The master cylinder it was attached

to, is the wrong size, but I'll see if I can flog it separately.

:: Thursday, November 17, 2011 ::

The carpeting is now complete!

Yes, I finally managed to get time (and more glue) to finish the carpet-sticking. First, I trim and stick the areas around the rear roof hinge, taking

care that the wiring to the interior light can flex properly as the roof goes up and down. I also replace the two screws through the end of the trimmed hoop

that holds the rear edge of the roof down. I just need to buy some velcro to finish the join and give the edge of the hood something to stick to.

Then I move on to the passenger side of the transmission tunnel. That was easy enough, although it's a big slab of carpet so a wee bit difficult to

manouevre into place when it's tacky (as I discovered on the other side). The answer was to get it in place, then peel back the back half, glue it, then

peel back the front half and glue that.

Then the mat up in the bulkhead. It has a slot cut for the wiring loom where it comes through, but I mark and cut another tiny slit for the two bolts that

will hold on the hinge for the cover that drops down (that holds all the electrical gubbins up). The right angle plate is supposed to have the fuse / relay

box mounted on it, but mine never has. It's turned through 90 degrees here to give better access to those two hinge bolts.

Then the mat up in the bulkhead. It has a slot cut for the wiring loom where it comes through, but I mark and cut another tiny slit for the two bolts that

will hold on the hinge for the cover that drops down (that holds all the electrical gubbins up). The right angle plate is supposed to have the fuse / relay

box mounted on it, but mine never has. It's turned through 90 degrees here to give better access to those two hinge bolts.

Those electrical gubbins have taken a bit of a battering throughout this process, incidentally, they've been pushed this way and that as I work around them.

I'll check before I put it all back, but I hope that nothing has become disconnected!

Those electrical gubbins have taken a bit of a battering throughout this process, incidentally, they've been pushed this way and that as I work around them.

I'll check before I put it all back, but I hope that nothing has become disconnected!

Setting aside my worries of a dead electrical system once I get it all back together, I bash on with the floor mat under the passenger seat, and then

finally the footwell mat.

Next, the wee cubbyhole behind the gear lever. The kit includes a a bit of carpet that I couldn't identify at first, but this is what it's for. I hold the

edge against the top edges of the hole, and mark where the corners will be, with a permanent marker. Then 4 cuts upwards, about an inch or so long, and I

fold it into the cubby hole. Once I cut it slightly to length so that the edges meet up in one corner, it's perfect! I take it out, apply the spray adhesive

(I'm getting a bit woozy by this time!) and stick it back in. Then 3 more cuts in the 3 corners, more spray, and fold over the top edges and stick down. Then

there is a separate wee rectangle of carpet that fits into the base of the cubby hole.

Finally, I spray and stick down the parcel shelf carpet, and that's it! Done!

Weeeelll... I've got one bit of carpet left - it's to refinish that panel under the ECU. The one on the car has a handy wee pocket though, and I don't want

to lose that - but it won't match the rest of the carpet. I think I'll have to recover that as well or it's going to look silly. I'll see.

Right... what's next. I decide to start to refit the seat belts. I locate the seat belt reel hole by the simple expedient of pushing a drill through from

the wheelarch. Fit reel, fit bolt, fit nut and tighten. The top seat belt mounting is equally easy.

The bottom belt mounting, and the mounting for the stalk, are covered by the carpet, so I locate the holes by pushing a bradawl through (I know, I should

have marked them before I stuck the carpets down, but I was excited ok?) and then cutting a cross with my trusty stanley knife (other brands of finger-

slashing craft knives are available). Bolts through, tighten up, sorted!

At this point I have to stop to be a taxi, so I've still got the other side to do.

It's looking good though!

:: Friday, November 18, 2011 ::

I start off by installing the other seat belt - much the same procedure as yesterday.

Then it's on to the handbrake warning switch - and here I realise that I should have fed the wires under the carpet first. Never mind, I pull back the carpet

a tiny bit till I can see the switch screw holes in the tunnel, then make a wee slit in the carpet to line up with the holes, and another just behind that,

and push the wires through. Then I line up the screw holes, mount the switch and connect up the wires, then stick the carpet down again. It will all be hidden

by the handbrake gaiter anyway but this reduces the chance of the wire moving and getting chafed. Then I tape the excess wires to the top of the tunnel, but

I'll have to find better tape because masking tape (that was on it originally) doesn't stick very well.

Next, I need to reconnect the handbrake lever, but I've got other stuff to do, and it's a bit fiddly and I don't want to start it and not finish it. That's

my excuse for being too bleeding lazy (and cold, by the way, I forgot to mention it's baltic in my garage today).

So instead, here's some photos of progress so far:

The flash seems to make the carpet look a wee bit lighter than it is, it's really quite a dark blue. The flash also seems to pick up that the carpet pile

is lying in different directions where I've been smoothing it down - it doesn't really look as blotchy as that!

Later on, I get a phone call from a man called Neil, who was on Pistonheads yesterday, and wanted to see a Cerbera. I've agreed to meet him after he

finishes work, so I fire the car up, and set off. He's a bit of a BMW E30 collector, so he's not hard to spot in the car park. Surprisingly, he recognises

a purple Cerbera as well!

I take him for a wee run, but the roads are wet and greasy so - well officer, let's just say that timely but safe progress was made... When we get back

he says "I've got to dig down the back of the sofa for all my pennies - I've got to get me one of these". I think he's impressed. I'm not surprised - I've

owned it 3 years and it still impresses me!

:: Wednesday, November 23, 2011 ::

Well after another week (almost) of distractions (I hate it when work gets in the way, eh?) I get back to finishing the carpet again. I decide to open with

an easy starter - I'll put the footwell cover back on (the one that the ecu and all the electrics, sits on top of). It take a bit of wrestling into position

under all the gubbins, but I finally manage to get the hinge in place over the two setscrews. then, by wedging a spanner on the outside, between the bolt head

and the washer bottle, I am able to tighten then up with a long socket extension and a stubby ratchet handle.

Then I trim some velcro to the same shape as the old bits (that I kept carefully stored on the top of the dashboard for this purpose) and stick them along

the sides of the hood panel, to hold the edge of the roof down.

Then I trim some velcro to the same shape as the old bits (that I kept carefully stored on the top of the dashboard for this purpose) and stick them along

the sides of the hood panel, to hold the edge of the roof down.

Emboldened by my success (I know it's only two bolts and two strips of velcro, but every step's a good step, right?) I decide to tackle the unholy bitch of

a job that is replacing the handbrake lever and cable. First I put the lever through its mounting hole, and then wedge it in place with a bit of wood and

some packing pieces, across to the opposite sill. That means it stays in place while I crawl underneath and reach up between the gearbox and the chassis,

to grab the end of the handbrake cable, pull as much slack out of it as possible, and push the clamp bolt over the splined end of the lever.

Then it's a case of getting a couple of spanners down past the gear lever, and tightening up the clamp bolt, and then replacing the smaller bolt that hold

the pawl ratchet plate in place. Finally, another dive underneath to turn the cable adjuster back up until the lever moves just 3 clicks. Sorted. Not as

much of a bitch as it was the first time I did it. I'm still learning!

Then it's a case of getting a couple of spanners down past the gear lever, and tightening up the clamp bolt, and then replacing the smaller bolt that hold

the pawl ratchet plate in place. Finally, another dive underneath to turn the cable adjuster back up until the lever moves just 3 clicks. Sorted. Not as

much of a bitch as it was the first time I did it. I'm still learning!

For my next trick (as learned by the old dog) I shall drill 3 holes in the transmission tunnel, and secure therein 3 pop studs, handbrake gaiter for the

securing of.

So that takes us to here - handbrake and switch refitted, ready for the centre console.

So that takes us to here - handbrake and switch refitted, ready for the centre console.

While I've got the drill out, I use a sharp thingy (I don't know what it is, it's sharp and it's got a handle - oh yes, a bradawl, that's it!) pushed up

through the floor, to show me where I have to make holes in the carpet - 4 each side for the seat bolts, and 2 each side for a pair of push fasteners that

seem to hold the front edge of the rear section down. Then I drill through the carpet, making sure I don't enlarge the holes in the body tub. The two front

ones (for the clips) are right above the outrigger crossmembers, so I also have to be carful not to drill holes in the top of those!

Then I test fit the centre console, and it's as tight as a wossname - the new carpets are much thicker than the old ones (which were, basically, threadbare)

so the console is going to need a bit of shoving to get it in place. It looks good though!

Before I fit it, though, I need to fit the rubber gaiter to the gear lever - it's hidden by the leather gaiter but you need it to keep fumes and draughts

out. The one I bought when I lifted the body isn't really a very good fit, so I decide to repair the original one I took off. I glue it together, and then

reinforce it with some rubber strip I bought to draughtproof the garage door. You can see it in the photo of the handbrake above - it's not perfect but it'll

do! I'll let it dry before I fit it though.

That's all the excuse I need to call it a day!

Next steps are console and seats - then it's on to the brake servo replacement!

:: Saturday, November 26, 2011 ::

First I refit the rubber gear gaiter, using little screws and flat washers.

Then it's on to replacing the centre console, First I get myself upside down in the footwell and reconnect the wiring loom, making sure that I route the

wiring properly past heater hoses etc. Then I clip the two fresh air hoses on to the rear of the eyeball vents, and push the console into position, making

sure I have the radio connectors free, and also tucking way the bulb holder for the "fibre optic" switch illumination. I check that I haven't trapped any

wiring between the console and the dash, and then lower the rear of the console into place. Well when I say "lower" I mean heave it into position - the

new carpets are much thicker and the console isn't very keen on fitting into position. I put in the two screws securing the rear of the console to the

tunnel, and then admire my handiwork

At this point I notice that I forgot to put the leather gear lever over the rubber one, so I have to remove the screws, and lift the console, and repeat

the heaving to fit, in the last bit. That's better!

Then I fit the gear knob and the handbrake lever handle.

Then I fit the gear knob and the handbrake lever handle.

Then I tidy up the wiring in the passenger footwell, and lift it all up into place and push the footwell cover into place. Because it's been in the shade

and not exposed to the sun (or to the dampness in the footwell) it has hardly faded at all, so I think I'll leave it with the original map pocket in place.

Then I tidy up the wiring in the passenger footwell, and lift it all up into place and push the footwell cover into place. Because it's been in the shade

and not exposed to the sun (or to the dampness in the footwell) it has hardly faded at all, so I think I'll leave it with the original map pocket in place.

I don't want to fit the driver's seat yet, because I'll need access to the servo and brake pedal. The passenger seat can go in though - it's relatvely

easy, just 4 bolts through the floor (which are already fixed to the seat frame) with big washers.

I don't want to fit the driver's seat yet, because I'll need access to the servo and brake pedal. The passenger seat can go in though - it's relatvely

easy, just 4 bolts through the floor (which are already fixed to the seat frame) with big washers.

That's about as much as I can do, before I start on the brake servo. Tomorrow!

I should have put back the radio though, but I forgot...

:: Sunday, November 27, 2011 ::

I forgot to recharge the camera as well, so no photos today! I'm getting worse...

After procrastinating for as long as I possibly can, because it's freezing cold in the garage, I finally make a start to the brake servo.

I use a vacuum pump to remove the brake fluid from the reservoir. Once that's empty, I open both front brake nipples and one of the rear ones, and drain

some fluid down to empty the master cylinder and pipes as much as I can.

Then it's into the footwell to remove the split pin and push out the clevis pin from the brake pedal.

The next step is to remove the vacuum hose from the servo (it just pulls out) and then the two rubber hoses connecting the reservoir to the master cylinder.

They are held on with jubilee clips so that doesn't take long. Then I disconnect the three metal brake pipes from the master cylinder, and move them

carefully aside. The master cylinder unbolts from the servo and after I've made sure it's empty, I set it aside.

Then I use a long extension bar and 13mm socket to remove the 4 nuts in the footwell, holding the servo to the bulkhead. That lets me jiggle the servo

free and off the car.

The two servos look identical, although the master cylinders aren't - the new one's mounting holes are 90 degrees out from the old one, so the servo has to

be turned by that amount. The mounting bolts to the bulkhead are offset though - two are further from the centre than the other two. To turn the servo, then,

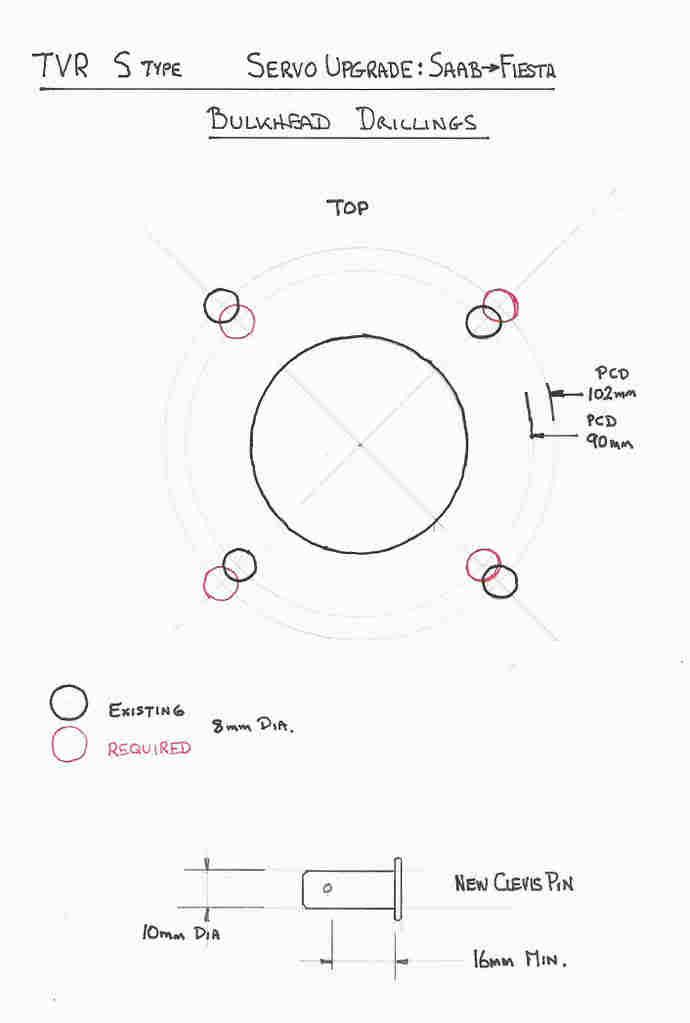

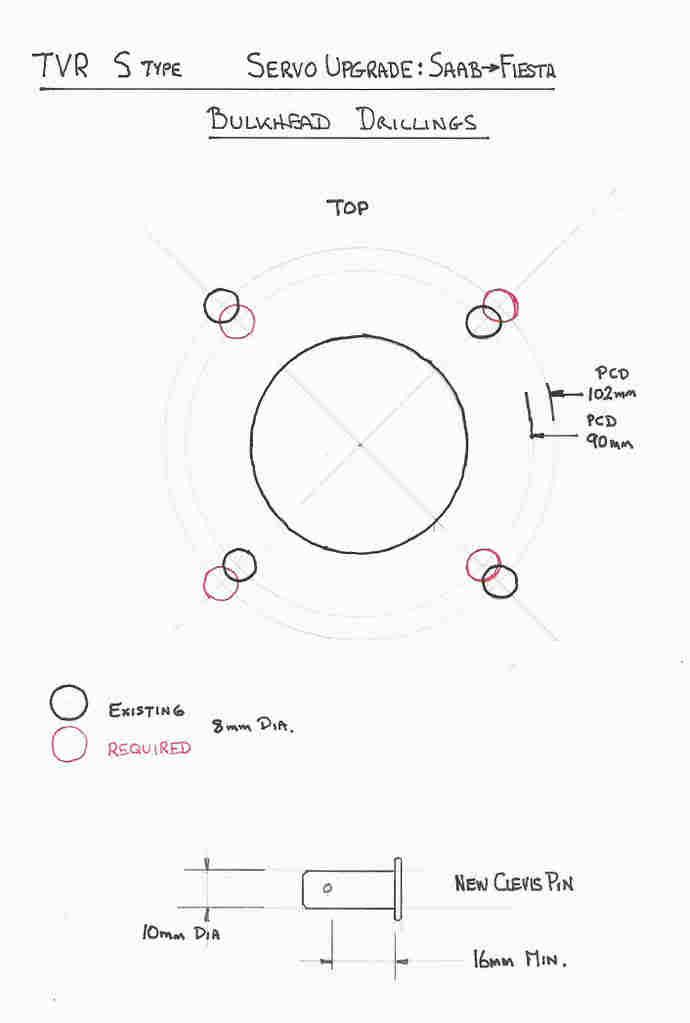

you have to re-drill the bulkhead according to this template, courtesy of Richard Jarvis:

Two diametrically opposite holes have to go CLOSER, from 102mm apart, to 90mm apart. The other two diametrically opposite holes have to go OUT from 90mm to

102 mmm. Now you'll see there that all the holes are supposed to be 8mmm diameter, and that the offset between the old hole and the new one is 6mm - that

means that the centre of the new hole is only 2mm from the edge of the old hole. My problem, though, is that the existing holes seem to all be 10mm dia, so

the new hole centre is right on the edge of the old one - so there's no way of getting a drill to stay in place and drill down the new centre.

What it seems I need to do, is file the two inner holes outwards by 6mm, and the two outer holes inwards by the same amount, to make oval holes, and then

bolt the servo in with plenty sealant and big washers on the inside to clamp it against the metal pedal box. I haven't got a round file though (I've got

half of one that I broke, but that's no bloody use).

I start to remove the old brake fluid reservoir, but the nuts on the inside are almost inaccessible up behind the dash, and I can't hold a spanner on them

AND turn the bolt on the outside at the same time. I need the help of a glamorous assistant, but I haven't got one - it's too cold so they are all tucked

up in the house. I can hardly feel what I'm doing either by this time, and visitors have arrived, so I call it a day.

My hands are too manky to install the radio anyway (honest, it's not that I just can't be arsed, no - look my hands are manky and I don't want to get that

all over the upholstery do I?...)

:: Wednesday, November 30, 2011 ::

It's St Andrews Day today. To celebrate in traditional style, I painted half my face blue and had haggis for my dinner. Patriotic to the core, me.

I finally manage to get on with the car. I bought a couple of wee grinding burrs for my dremel, that should be able to enlarge the mounting holes for the

servo.

First I stick masking tape over the existing holes in the bulkhead, to give me something to mark on. Then I take the template I made, and mark through the

edges of the enlarged holes - two to be elongated outwards, the other two inwards.

First I stick masking tape over the existing holes in the bulkhead, to give me something to mark on. Then I take the template I made, and mark through the

edges of the enlarged holes - two to be elongated outwards, the other two inwards.

Then using the grinding burrs, I grind back the fibreglass to the marks I made - that's easy. Then the difficult bit is grinding back the metal of the

pedal box, to the same shape. I do a few trial fits of the old servo, turned through 90 degrees, and gradually grind and file the metal back until the

servo slips into place. While I'm doing that, incidentally, I notice that there's brake fluid dripping out of the old servo - the master cylinder has

obviously started leaking, so I'm changing it none too soon!

Then using the grinding burrs, I grind back the fibreglass to the marks I made - that's easy. Then the difficult bit is grinding back the metal of the

pedal box, to the same shape. I do a few trial fits of the old servo, turned through 90 degrees, and gradually grind and file the metal back until the

servo slips into place. While I'm doing that, incidentally, I notice that there's brake fluid dripping out of the old servo - the master cylinder has

obviously started leaking, so I'm changing it none too soon!

Then I remove the masking tape. I'll have to clean off some old sealant that was between the servo and the bulkhead, and also various other bits of sealer

etc on the bulkhead.

Then I remove the masking tape. I'll have to clean off some old sealant that was between the servo and the bulkhead, and also various other bits of sealer

etc on the bulkhead.

First, though, I need to drill a bigger hole in the brake pedal. The old servo had an 8mm clevis pin, but the new one has a 10mm pin. Access is restricted

so I bought a right-angle drill adapter. Even then, the clutch pedal is in the way... so I find a bit of wood the right thickness and lift the brake pedal

back, and brace it on the wood. Then (and here's the enginuity, although I say so myself) I feed my trusty webbing strap through the centre of the steering

column bearing, round the clutch pedal and then back through the bearing. Then a knot in the strap, a tyre lever through the loop, braced against another

bit of wood against the chassis, to hold the clutch pedal down out of the way.

The right angle attachment works well, right up to the point where it suddenly doesn't - when it's almost through the pedal, it suddenly stops turning. A

brief diagnostic check confirms that, in my expert engineering opinion, it's fucked. A fuller diagnosis would be that the internal gearing isn't engaging

any more, but the simple explanation is enough. It was brand new and didn't even finish one hole. Take a good look at the photo. Avoid.

The right angle attachment works well, right up to the point where it suddenly doesn't - when it's almost through the pedal, it suddenly stops turning. A

brief diagnostic check confirms that, in my expert engineering opinion, it's fucked. A fuller diagnosis would be that the internal gearing isn't engaging

any more, but the simple explanation is enough. It was brand new and didn't even finish one hole. Take a good look at the photo. Avoid.

I need to buy a better one. Oh, and take that one back and recoup my hard-earned dosh, obviously.

So that leaves me here: I need to finish the clevis pin hole, then put the thing back together with big washers to secure the servo to the bulkhead.

So that leaves me here: I need to finish the clevis pin hole, then put the thing back together with big washers to secure the servo to the bulkhead.

It's now dinner time so that'll do for today. Haggis here I come!

Then I cut through the carpet in line with the holes in the bulkhead, and then install the roof hinge bolts, tighten up the nuts inside the pillar, and then

restick the carpets down. Then I trim along the rear of the door gap, and then reinstall the door seals around the edges of the tub.

Then I cut through the carpet in line with the holes in the bulkhead, and then install the roof hinge bolts, tighten up the nuts inside the pillar, and then

restick the carpets down. Then I trim along the rear of the door gap, and then reinstall the door seals around the edges of the tub.

Then I mark through the holes for the roof struts, and drill through the carpet from the boot, then reinstall the struts. The door rubbers aren't finished

in this photo - I need to finish trimming the carpet around the tops of the door pillars first.

Then I mark through the holes for the roof struts, and drill through the carpet from the boot, then reinstall the struts. The door rubbers aren't finished

in this photo - I need to finish trimming the carpet around the tops of the door pillars first.